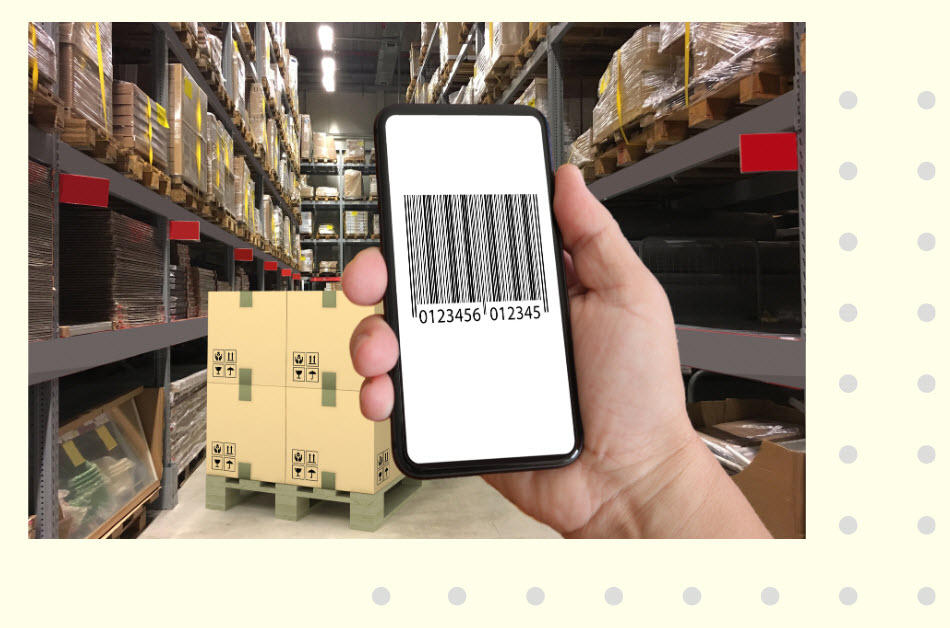

Barcoding Technology

In the supply chain process, barcoding is a technology that provides a barcode label to each inventory item in order to confirm the accuracy of the product details

and trace the inventory item throughout the supply chain. Barcoding technology has several benefits in the Transport Management System, including:

- Ensure accurate product details: Barcoding provides accurate information of the product details in the Delivery Order Management to ensure accurate product details: Barcoding accuracy of all information included in this product.

- Minimizing shrinkage and loss: With the use of barcoding, it helps to reduce the likelihood of incomplete inventory items and loss by providing accurate and real-time data on inventory levels and locations.

- Accurate confirmation of receiving and deliveries: Barcoding enables couriers and transport personnel to confirm warehouse receiving and consignee deliveries quickly and accurately, reducing the likelihood of errors and improving customer satisfaction.

- Tackling counterfeiting: Barcoding can help to prevent counterfeiting by providing a unique identifier for each item to ensure that the same product is received and delivered in the whole supply chain system because of track and trace features.

- Enabling product recalls: In the event of a product recall, barcoding can help to identify the affected products quickly and accurately, reducing the risk of harm to consumers.

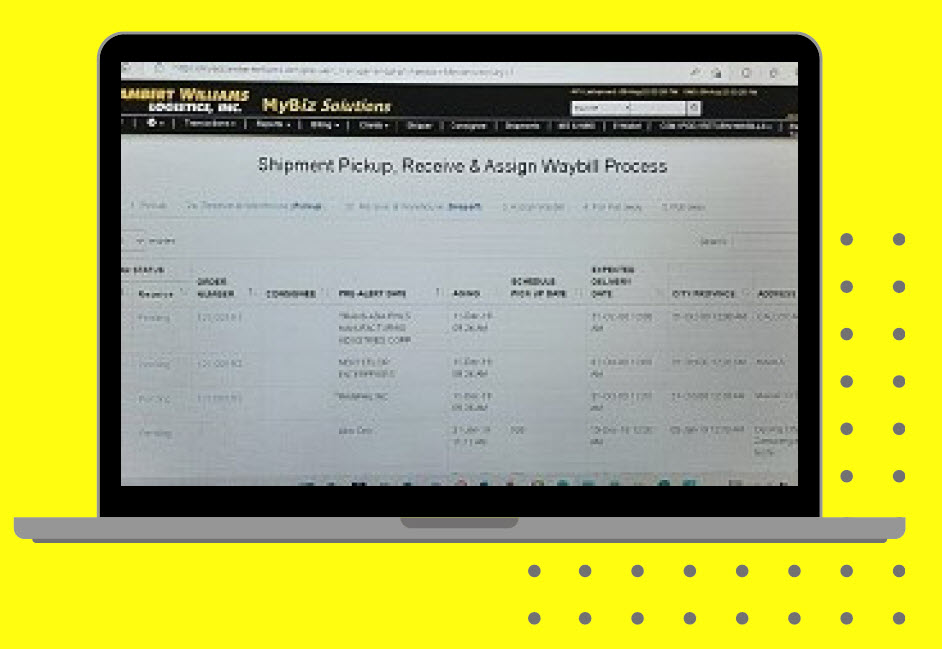

Delivery Order Management

Our order management has seamless integration of order data originating from multiple systems from our clients to the transmission of their order placement to our MyBiz Cloud system. Our order management module is integrated with:

- Our Pre-alert Management that employs an effective implementation of EDI (Electronic Data Interchange) for the seamless flow of data throughout our supply chain. The EDI implementation ensures that we are not burdened by the heavy use of paper-based documentation

- Generating optimal routing plans for the orders. Preparing contingency plan for changes in transportation demands contingency plan for changes in transportation demands based on the types of orders

- Preparing contingency plan for changes in transportation demands based on the types of orders

- Synchronized delivery processes to match customer expectations (in the case of speed deliveries)

- Integration of delivery data

Freight Management

Freight management is an important aspect in our supply chain operation.

We are able to update freight charges to you in our carrier management assisting us in our cost estimation and financial planning.

Using this feature, we can calculate freight tariffs of carriers , which may vary from the specific area in the Philippines.

Transportation

Our crucial module in our TMS which contributes to making our supply chain lean and efficient has the following features:

- Route optimization and consolidation

- Seamless Tracking and Tracing providing updates of freight delivery documents by digitizing them and using a digital interface and mobile applications for information updates

- Fleet capacity management. The ability to facilitate easy communication between stakeholders by effectively using collaboration tools. Instant mobile notifications are must-have feature in our process

- Analytics and reporting module

- Digitized processes generate big data that includes Fleet and freighter tracking of our carrier provider, as well as information management

- Customer Service Features

Analytics and Reporting

Digitized processes generate big data which we have to refine to

provide you with this information that we utilize to gain insights

into our operational efficiency.

Our analytics and reporting include the collection, analysis, and

summary of transportation and supply chain metrics across our

organization featuring:

- Customized Reports

- KPI Performance

- Customer Service Features